5. LPG Vehicle Systems A Cleaner Alternative

5. LPG Vehicle Systems A Cleaner Alternative

In various industries, maintaining a consistent pressure is crucial for the safety and efficiency of operations. Pressure regulating devices play a vital role in achieving this stability. These devices are designed to automatically maintain the pressure within a specified range, ensuring that equipment operates optimally and safely.

1. American Heart Association (AHA)

In addition to safety, natural gas pressure regulators contribute to the efficiency of gas distribution systems. By maintaining optimal pressure levels, regulators help to minimize gas loss during transmission. Efficient systems reduce overall energy consumption and costs for both providers and consumers. Additionally, a well-regulated supply ensures consistent quality of service, which is essential for appliances that rely on natural gas.

Electric auxiliary heaters play a vital role in modern heating systems, especially in vehicles and buildings where efficient climate control is essential. As temperatures drop, these heaters provide a supplementary source of warmth, ensuring comfort and energy efficiency. This article delves into the functionality, applications, and benefits of electric auxiliary heaters.

- Diving and Aviation In recreational diving, pressure vessels are used to store breathing gases, such as compressed air or specialty gas mixtures. Similarly, in aviation, gas cylinders are employed for various functions, including cabin pressurization.

3. Increased Data Quality Coalescing filters help maintain a cleaner dataset by removing duplicates and irrelevant data, which in turn improves the quality of insights derived from the data.

In recent years, the conversation surrounding energy has grown increasingly complex, as nations strive to balance economic growth, environmental sustainability, and energy security. A crucial player in this dialogue is natural gas, a fossil fuel that has emerged as a significant complement to renewable energy sources in the transition toward a cleaner energy future. Given its accessible nature, relatively lower emissions compared to other fossil fuels, and versatility across various applications, natural gas undoubtedly holds a prominent position in the contemporary energy landscape.

Gas filters are indispensable in the modern industrial environment, providing essential solutions for air pollution control and compliance with environmental standards. As industries continue to evolve, the demand for effective gas filtration will only grow, driving innovation and the development of advanced technologies. By adopting efficient filtration systems, industries can not only protect the environment but also enhance their operational performance and ensure a healthier future for all.

The geographic location of distribution stations also plays a crucial role in their effectiveness. Strategically positioned distribution centers can significantly reduce lead times, ensuring that products reach their destination quickly. Businesses often consider factors like proximity to major highways, ports, and customer demographics when selecting locations for their distribution stations. This strategic positioning not only optimizes logistics but also enhances a company’s competitive edge in the market.

The integration of efficient filtration systems has a direct impact on the energy efficiency of natural gas operations. Clean gas means lower maintenance costs, reduced downtime, and enhanced performance of compressors and turbines. Moreover, effective gas filtration can improve the thermal efficiency of natural gas combustion, resulting in lower greenhouse gas emissions.

How Electric Water Heaters Work

Conclusion

Understanding Electric Heaters A Comprehensive Guide

The benefits of using advanced filtration technologies extend beyond just improving gas quality. They also contribute to environmental sustainability. Cleaner natural gas translates to lower greenhouse gas emissions when burned, reinforcing its role as a transitional fuel toward entirely renewable energy sources. Furthermore, by reducing impurities, filtration technologies help to minimize the risk of environmental contamination, which is crucial for preserving ecosystems near natural gas extraction and processing sites.

A blood pressure regulator device is designed to monitor and manage the blood pressure of individuals, particularly those diagnosed with hypertension. These devices leverage advanced technology to provide users with accurate readings and real-time monitoring, allowing for timely interventions when necessary. The device typically consists of a digital monitor, a cuff that wraps around the upper arm, and a digital display that shows the readings.

فلتر. Email filters, for instance, help sieve spam and unwanted messages, ensuring a streamlined communication process. Social media algorithms filter content based on user preferences, creating personalized news feeds. While this improves user experience, it can also lead to echo chambers, limiting exposure to diverse perspectives.

فلتر. Email filters, for instance, help sieve spam and unwanted messages, ensuring a streamlined communication process. Social media algorithms filter content based on user preferences, creating personalized news feeds. While this improves user experience, it can also lead to echo chambers, limiting exposure to diverse perspectives.Cyclone separators have emerged as a vital technology in various industrial processes, particularly for dust control and the efficient separation of particles from gases and liquids. These centrifugal separators are widely used across multiple sectors, including manufacturing, mining, and food processing, to clean air streams, enhance product quality, and protect equipment from wear and tear caused by particulate matter.

In conclusion, pneumatic control valves are indispensable components in fluid control systems across various industries. Their ability to manage the flow of gases quickly and reliably contributes to enhanced efficiency, safety, and productivity in industrial processes. As technology advances, the role of these valves will continue to evolve, integrating with automation systems to meet the growing demands of modern manufacturing and engineering. Therefore, understanding and utilizing pneumatic control valves effectively can lead to significant benefits for any organization reliant on pneumatic applications.

The measurement of gas is a crucial aspect of various industries, ranging from energy production and environmental monitoring to healthcare and food processing. Accurate gas measurement is essential for safety, efficiency, and regulatory compliance. This article explores the significance of gas measurement, the techniques employed, and its applications in different fields.

- Flexibility in Feedstock Gasifiers can process a wide range of feedstocks, including agricultural residues, industrial waste, and even sewage, adapting to local resource availability.

The Importance of Precision Voltage Regulation Systems

Conclusion

In industrial settings, maintaining the integrity and safety of various systems is crucial. One of the key components that play a vital role in ensuring safety and operational efficiency is the relief valve, known in Arabic as صمام التنفيس (sām al-tanfīs). Relief valves are designed to protect equipment and systems from overpressure situations, which can lead to catastrophic failures, injuries, or environmental Hazards.

Additionally, CNG is abundant and domestically available in many parts of the world, which enhances energy security. The widespread use of CNG can lead to decreased reliance on imported oil, stabilizing energy prices and supporting local economies. As countries around the globe seek energy independence, the domestic production of natural gas is becoming increasingly important. For instance, the United States has seen a significant surge in natural gas production due to advancements in extraction technologies like hydraulic fracturing, leading to a shift in energy production strategies.

Benefits of Using Basket Strainers

Furthermore, educational institutions have begun to integrate stress management programs into their curricula, with organizations helping to deliver these initiatives. Programs that teach students about emotional intelligence, resilience, and coping strategies can significantly enhance their ability to manage stress effectively. By equipping younger generations with these vital skills, organizations contribute to building a more resilient society in the long run.

Moreover, pressure reducers help maintain a consistent output pressure even with varying inlet pressures. This capability is critical in processes where precise gas flow is essential—for instance, in welding, where maintaining a steady flame requires consistent gas pressure. Furthermore, in medical applications, such as in oxygen delivery systems, it is vital to provide patients with gas at a controlled and safe pressure to ensure their wellbeing.

Conclusion

Applications

In addition to liquefaction and regasification, heat exchangers are extensively used in natural gas processing plants, where they are involved in drying, purification, and heating of the gas. For instance, before natural gas is transported in pipelines, it often requires dehydration to remove water vapor, which can cause problems such as hydrate formation during transportation. Heat exchangers can assist in this process, leading to purer and more efficient gas delivery.

In addition to their technical functions, gas pressure reducers also offer economic benefits to industrial operations. By reducing the amount of gas needed to achieve a desired pressure, these devices can help to lower energy costs and improve overall efficiency. By ensuring that gas is used only as needed and not wasted through excess pressure, gas pressure reducers can help to save money and resources for businesses while also reducing their environmental impact.

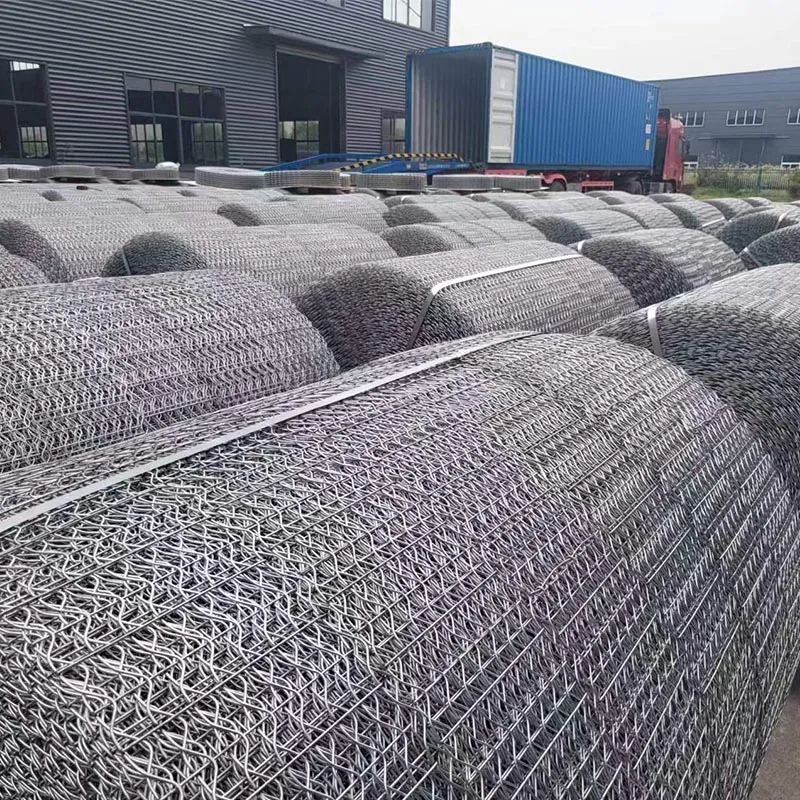

Additionally, shale screens are employed in erosion control measures along coastlines and riverbanks. By stabilizing the soil and preventing erosion, these screens help in maintaining the integrity of natural habitats and protecting against environmental degradation.

- Соҳаҳои саноатӣ Ҳангоми сохтани иншоот, тағйирот ва иваз кардани муколаҳои муосир бо пешниҳоди маводҳои дуруст, ба ҷойи конструктсияи хурсанде, ғалванизатсияшудаи оҳан ҳамчун имконият меравад.

Material Types and Their Costs

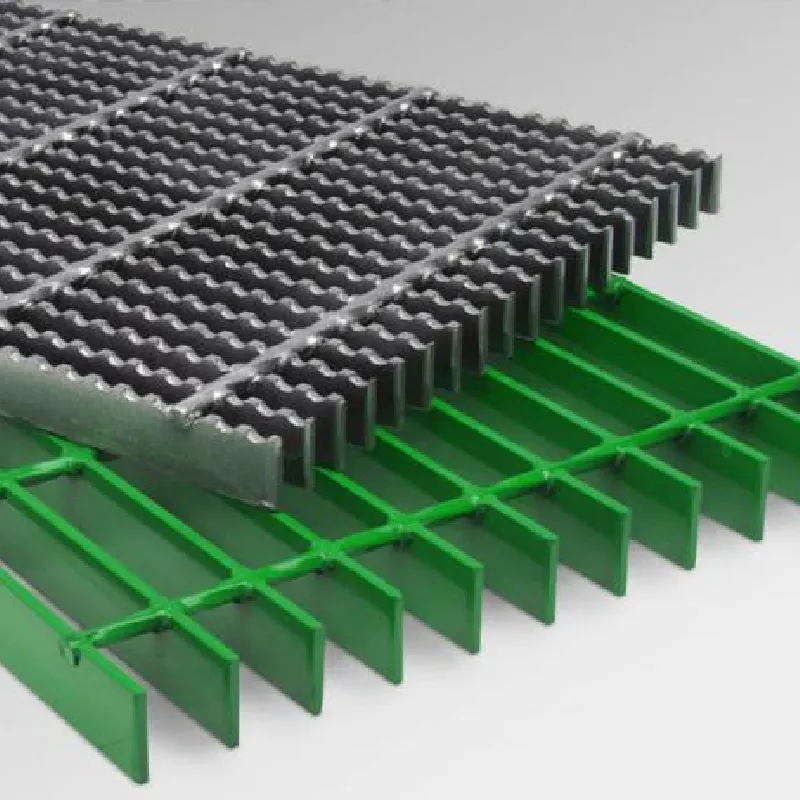

Inoltre, il pavimento in grigliato d'acciaio è facile da pulire e mantenere. La sua superficie liscia e aperta permette un rapido drenaggio dei liquidi, riducendo il rischio di slip e cadute. Questo lo rende ideale per applicazioni in cui la sicurezza è una priorità, come ristoranti, laboratori e aree di produzione alimentare. Grazie alla sua resistenza alla corrosione, è anche una scelta eccellente per ambienti esterni o situazioni in cui è esposto a sostanze chimiche.

4. Safety Regulations Compliance with local building codes and safety regulations is another critical factor. These regulations often specify minimum thickness standards based on the application, particularly in public areas where safety is paramount.

La grille métallique expansée est fabriquée à partir de feuilles de métal qui sont coupées et étendues pour créer une structure de maillage. Le terme 4% d'expansion fait référence au rapport entre la surface initiale du métal et sa surface après expansion. Cela signifie que le fil de métal est étiré pour créer des ouvertures qui représentent 4% de sa surface totale. Ces ouvertures permettent un excellent drainage, de la ventilation, ainsi qu'un poids léger tout en conservant une bonne résistance.

In addition to functional benefits, aluminium bar grating also offers aesthetic advantages. With a sleek, modern appearance, it can enhance the visual appeal of various structures. Available in a range of finishes and colors, aluminium grating can be customized to match any design scheme. This versatility allows architects and designers to incorporate aluminium grating into their projects, from industrial buildings to urban parks and public spaces.

Architecturally, galvanised steel grating also presents an aesthetic appeal. It is available in different designs, finishes, and sizes, allowing it to blend well with various environments while maintaining functionality. This adaptability makes it a popular choice for commercial developments and municipal projects.

1. Standard-Gitterroste Diese sind am weitesten verbreitet und werden oft in Industriebauten, Fußgängerwegen und als Abdeckungen für Gräben verwendet.

The production of hot dip galvanized steel grating involves several stages. Initially, raw steel bars are shaped into a grid pattern, forming the grating itself. This grid design allows for efficient drainage and visibility, making it ideal for numerous applications. The next crucial step is the hot dip galvanizing process, where the steel grating is submerged in a molten zinc bath at high temperatures. This process creates a robust protective layer of zinc, which adheres to the steel surface through a metallurgical reaction, providing long-lasting protection against corrosion and wear.